What Role Does a Conveyor Idler Play in Material Handling Systems?

2025-01-07

In many industries, conveyor systems are an essential component for transporting materials over various distances, whether in manufacturing, mining, or logistics. These systems rely on several critical components to ensure smooth, efficient, and reliable operations. One such component that plays a crucial role in the performance of conveyor belts is the conveyor idler. But what exactly does a conveyor idler do, and why is it so important in material handling systems? In this blog, we’ll explore the function of conveyor idlers, their types, and why they are indispensable for efficient and safe material transport.

What is a Conveyor Idler?

A conveyor idler is a type of roller or support used in conveyor systems to help support and guide the conveyor belt as it moves. Idlers are typically placed at various points along the conveyor system to prevent the belt from sagging, reduce friction, and keep the belt aligned with the system. These components are designed to carry the load of materials being transported while also ensuring that the conveyor belt operates smoothly without unnecessary wear and tear.

The Importance of Conveyor Idlers

1. Load Distribution:

Conveyor idlers play a key role in distributing the weight of the materials being transported across the length of the conveyor belt. By supporting the belt at multiple points, idlers ensure that the load is evenly spread out. This helps to prevent sagging, which could cause damage to the belt or inefficient operation.

2. Belt Alignment:

Maintaining proper belt alignment is crucial for the smooth functioning of a conveyor system. Idlers help keep the conveyor belt centered and aligned along its intended path. Misalignment can lead to increased wear on the belt, reduced efficiency, and even system failure. Idlers help prevent this by providing continuous support and alignment.

3. Friction Reduction:

Conveyor idlers reduce the amount of friction between the conveyor belt and the supporting structure. This is essential to prevent the belt from overheating or suffering damage from excessive wear. By reducing friction, idlers also contribute to the energy efficiency of the system, ensuring that the conveyor motor does not have to work harder than necessary to move the belt.

4. Improved Durability and Longevity:

Conveyor belts are subjected to constant stress from the weight of the material being transported, as well as the tension required to keep the belt moving. Over time, this can cause significant wear and tear on both the belt and the structure of the conveyor system. Idlers, by providing support and reducing friction, help to prolong the life of both the belt and the entire system.

5. Safety:

Conveyor systems can present safety hazards if not properly maintained. A sagging or misaligned belt can cause jams, increased friction, or even belt failure. Idlers help to keep the system running smoothly, reducing the risk of these hazards and ensuring the safety of the operation.

Types of Conveyor Idlers

There are several types of conveyor idlers, each designed for different functions and operating conditions. Here are the main types:

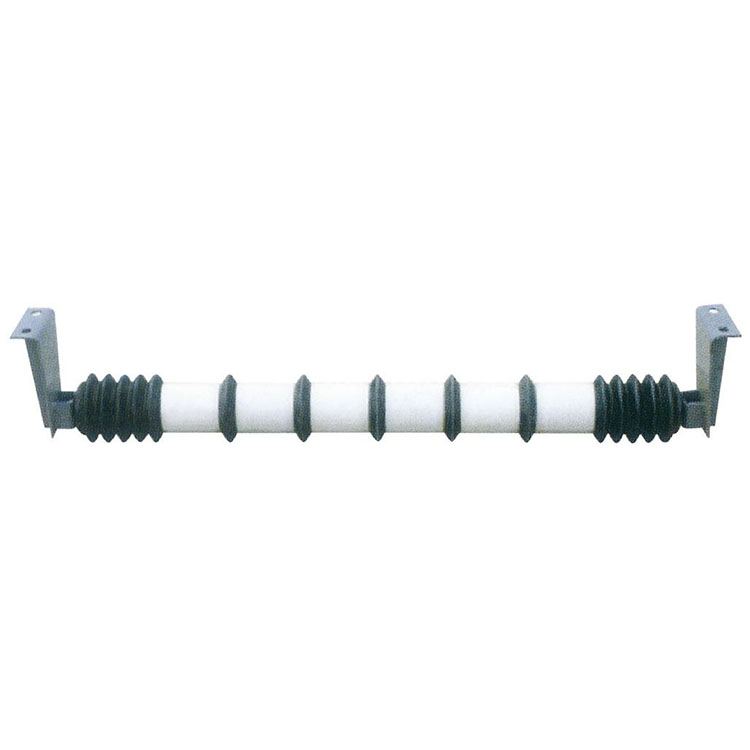

1. Impact Idlers:

These are used at the loading zone of the conveyor, where materials are introduced to the belt. Impact idlers are designed to absorb the shock from heavy or abrasive materials and protect the belt from damage. They typically have more robust construction to handle the force generated by material loading.

2. Return Idlers:

These idlers are located underneath the conveyor belt, supporting the return side of the belt as it moves back to the starting point. Return idlers prevent the belt from sagging and help maintain its proper tension during the return phase.

3. Troughing Idlers:

Troughing idlers are commonly used to support the carrying side of the belt, which holds the material being transported. They are designed in a "V" shape, which helps keep the material on the belt and prevents it from spilling off the sides. These idlers are typically placed at intervals along the conveyor to provide continuous support.

4. Self-Cleaning Idlers:

These idlers feature a design that allows for the automatic removal of material buildup from the belt as it moves. This is particularly important in environments where sticky or wet materials are being transported, as it prevents material from accumulating on the idlers and belt, which could cause blockages or damage.

5. V-Groove Idlers:

V-Groove idlers are typically used to guide the belt and keep it aligned. They have a grooved design that provides a precise pathway for the conveyor belt, preventing it from drifting off course.

6. Carrying Idlers:

These are the most common type of idlers used along the conveyor’s load-carrying section. They are designed to support the weight of the material being transported and ensure the belt stays flat and aligned as it moves.

7. Return Rollers:

Return rollers are used on the return side of the conveyor belt. They help maintain belt tension, reduce sagging, and ensure smooth return movement without unnecessary friction.

How to Choose the Right Conveyor Idler

Choosing the right conveyor idler depends on several factors, including the type of material being transported, the environment, and the specific needs of your conveyor system. Here are a few things to consider when selecting conveyor idlers:

1. Material Type:

Different materials require different types of support. For example, heavier materials may need stronger impact idlers, while lighter materials might only require standard carrying idlers.

2. Environmental Conditions:

Consider the environment in which the conveyor system operates. If the area is dusty, wet, or has extreme temperatures, you may need special idlers designed for those conditions, such as corrosion-resistant or self-cleaning idlers.

3. Belt Size:

The size of the conveyor belt will also affect your choice of idler. Larger belts will require idlers with a greater load capacity and sturdier construction.

4. Maintenance Needs:

Some idlers require more frequent maintenance than others. For example, self-cleaning idlers may reduce the need for manual cleaning, while traditional idlers may need to be checked and cleaned periodically.

5. Cost Considerations:

Conveyor idlers come in a range of price points. While it’s important to choose idlers that meet your operational requirements, it’s also necessary to keep your budget in mind.

Conclusion: The Backbone of Efficient Conveyor Systems

In conclusion, conveyor idlers are critical components that ensure the smooth operation, efficiency, and longevity of a conveyor system. Whether it's distributing the load, reducing friction, or maintaining alignment, idlers contribute significantly to the overall performance of the system. By selecting the right type of idler and maintaining it properly, you can improve the efficiency of your material handling operations, reduce downtime, and increase the lifespan of your conveyor system.

As conveyor technology continues to advance, idlers will remain an essential part of the equation for businesses looking to streamline their processes and keep their operations running smoothly.