The Future of Lamination: Exploring the Multifunctional Automatic Laminating Machine

2024-08-14

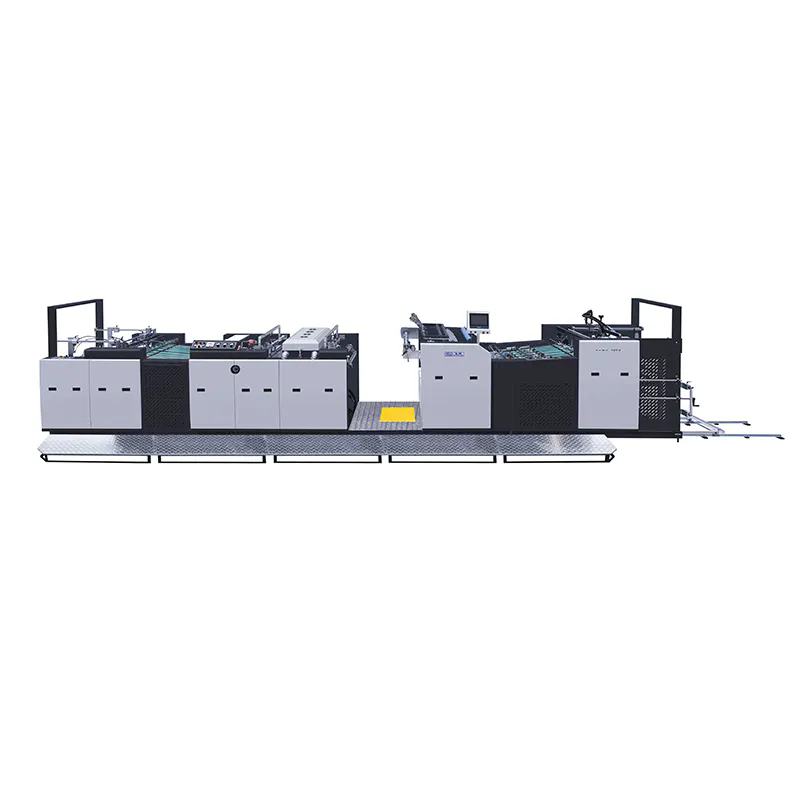

Lamination is a critical process in various industries, ensuring that products are durable, visually appealing, and protected from wear and tear. As technology continues to evolve, the Multifunctional Automatic Laminating Machine is setting a new standard in the laminating industry, offering unmatched versatility, efficiency, and precision. This blog explores the key features, benefits, and applications of this advanced machine, highlighting why it is becoming an essential tool in modern production environments.

Understanding the Multifunctional Automatic Laminating Machine

A Multifunctional Automatic Laminating Machine is an advanced piece of equipment designed to automate the lamination process for a wide range of materials, including paper, cardboard, plastic, and more. Unlike traditional laminating machines, this multifunctional version can handle various lamination tasks—such as thermal, cold, and pressure-sensitive laminating—without requiring manual intervention. Its ability to perform multiple functions makes it ideal for businesses that require high-quality lamination across different materials and formats.

Key Features of the Multifunctional Automatic Laminating Machine

1. Multi-Process Capabilities

This machine is designed to handle a variety of laminating processes, including hot and cold lamination, UV coating, and foil stamping. Whether you need to create glossy, matte, or textured finishes, the Multifunctional Automatic Laminating Machine can do it all. This flexibility eliminates the need for multiple machines, saving space and reducing equipment costs.

2. High-Speed Operation

Speed is a crucial factor in any production line. The Multifunctional Automatic Laminating Machine is engineered for high-speed operation, allowing you to laminate large volumes of material in a fraction of the time compared to traditional methods. This increased throughput makes it an excellent choice for businesses with high production demands.

3. Advanced Control System

Precision is vital in lamination, and this machine delivers with its advanced control system. Equipped with digital sensors and automated adjustments, the machine ensures perfect alignment and uniform lamination across every sheet. The touch-screen interface allows operators to easily adjust settings, monitor the process, and ensure consistent results.

4. Energy Efficiency

Sustainability is a growing concern for many businesses. The Multifunctional Automatic Laminating Machine is designed with energy efficiency in mind, reducing power consumption without compromising performance. Its smart energy-saving features not only lower operating costs but also contribute to a greener production process.

5. User-Friendly Design

Despite its advanced capabilities, the Multifunctional Automatic Laminating Machine is user-friendly. The intuitive control panel and straightforward operation make it accessible for operators of all skill levels. Additionally, the machine requires minimal maintenance, reducing downtime and ensuring smooth operation.

Benefits of Using a Multifunctional Automatic Laminating Machine

1. Enhanced Productivity

By automating the lamination process, this machine significantly boosts productivity. Its ability to handle multiple tasks simultaneously reduces the need for manual intervention, allowing your team to focus on other critical aspects of production.

2. Cost-Effective

The multifunctionality of the machine reduces the need for multiple pieces of equipment, leading to cost savings in terms of both capital expenditure and operational costs. Its durability and low maintenance needs further enhance its cost-effectiveness.

3. Consistent Quality

Consistency is key to maintaining high product standards. The Multifunctional Automatic Laminating Machine ensures uniform quality across all laminated materials, enhancing the overall look and feel of your products.

4. Versatile Applications

Whether you're in printing, packaging, or manufacturing, this machine is versatile enough to meet a variety of needs. From laminating business cards and brochures to creating durable packaging and labels, the possibilities are endless.

Applications in Various Industries

The Multifunctional Automatic Laminating Machine finds applications across multiple industries:

- Printing: Ideal for laminating posters, book covers, business cards, and other printed materials to give them a professional finish.

- Packaging: Enhances the durability and appeal of packaging materials, making products more attractive to consumers.

- Manufacturing: Used to create durable, laminated labels, stickers, and other components that require long-lasting protection.

Conclusion

The Multifunctional Automatic Laminating Machine represents the future of lamination technology, offering unmatched versatility, efficiency, and precision. By integrating this machine into your production line, you can improve productivity, reduce costs, and deliver consistently high-quality products. Whether you're looking to upgrade your existing lamination process or invest in new equipment, the Multifunctional Automatic Laminating Machine is a smart choice for businesses aiming to stay ahead in a competitive market.

Embrace the future of lamination today and discover how the Multifunctional Automatic Laminating Machine can transform your production process!