The Future of 3D Printing with PEEK: A Revolution in Manufacturing

2025-03-21

In the ever-evolving world of 3D printing, new materials continue to open up new possibilities for industries ranging from aerospace to medical devices. One such material that is making waves in the world of 3D printing is PEEK, or Polyetheretherketone. Known for its exceptional properties, PEEK is quickly becoming a go-to choice for manufacturers looking to create high-performance parts and products. In this blog, we will dive into what PEEK 3D printing is, its benefits, applications, and how it is shaping the future of manufacturing.

What is PEEK?

PEEK is a high-performance thermoplastic polymer that is known for its remarkable strength, durability, and resistance to extreme temperatures. It is part of a family of polyaryletherketones and is widely used in applications where traditional materials would not be able to withstand harsh environments. PEEK can tolerate temperatures up to 480°F (250°C) and is highly resistant to chemical corrosion, making it ideal for industries like aerospace, automotive, medical, and oil and gas.

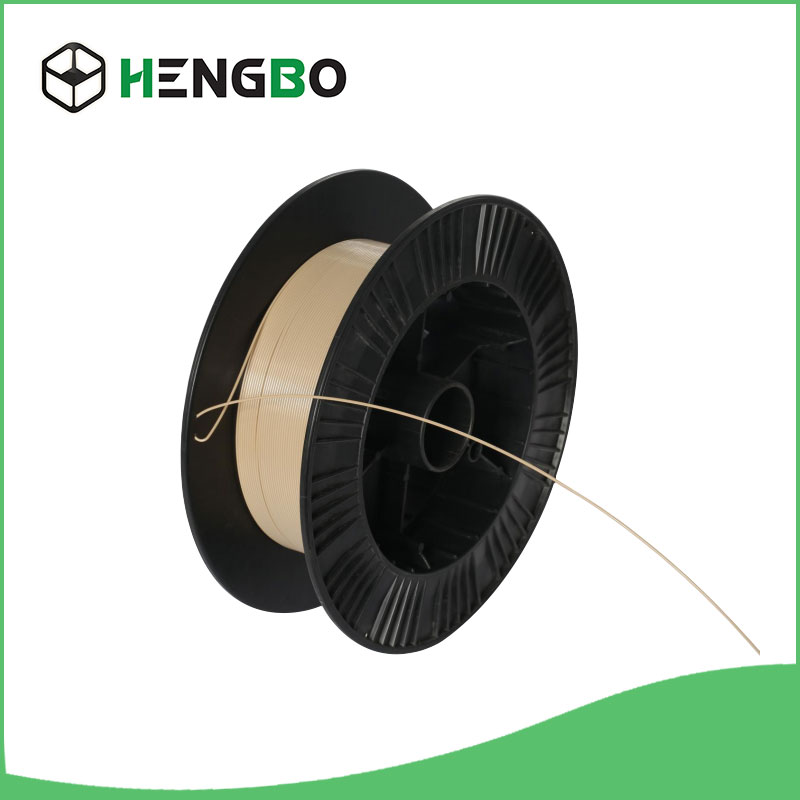

In 3D printing, PEEK is typically used as a filament for fused deposition modeling (FDM) 3D printers. Its high melting point and excellent mechanical properties make it an excellent choice for producing parts that need to perform under demanding conditions. However, PEEK printing requires a specialized 3D printer capable of handling high-temperature materials, as most standard 3D printers are not designed to reach the temperatures required for PEEK to be processed.

The Benefits of PEEK 3D Printing

1. Exceptional Strength and Durability

One of the key advantages of PEEK is its high strength-to-weight ratio, which allows it to perform well under extreme mechanical stresses. PEEK printed parts are incredibly durable, offering long-lasting performance even in tough conditions. This makes it a perfect material for producing parts that need to endure significant wear and tear, such as gears, bearings, and structural components.

2. Heat Resistance

PEEK’s ability to withstand high temperatures without deforming or losing strength is one of its standout features. It can handle continuous exposure to temperatures up to 250°C (482°F) without experiencing degradation, making it ideal for industries that require components to operate in high-heat environments, such as the aerospace and automotive industries.

3. Chemical and Wear Resistance

In addition to its heat resistance, PEEK is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes it an ideal material for parts exposed to harsh chemicals, such as seals, pumps, and valves in the chemical processing industry. Furthermore, its resistance to wear and friction allows PEEK parts to maintain their functionality over long periods of use, reducing the need for frequent replacements.

4. Biocompatibility

For the medical industry, biocompatibility is a crucial factor in selecting materials for implants, surgical instruments, and other medical devices. PEEK has been extensively tested and proven to be biocompatible, which means it is non-toxic and safe to use in direct contact with the human body. It is commonly used for creating patient-specific implants, spinal fusion devices, and other medical components that require both strength and biocompatibility.

5. Electrical Insulation

PEEK also serves as an excellent electrical insulator, making it useful in electronic and electrical applications. Its insulating properties are crucial when producing components like connectors, sensors, and electrical housings that need to perform reliably without conducting electricity.

Applications of PEEK 3D Printing

1. Aerospace Industry

The aerospace industry relies on materials that can withstand extreme temperatures, high pressure, and mechanical stress. PEEK is ideal for these applications, especially in producing lightweight, durable components such as brackets, housings, and fittings. Since the aerospace sector is highly focused on reducing weight without sacrificing performance, PEEK's combination of strength and lightness makes it a highly desirable material for parts used in aircraft and spacecraft.

2. Medical and Healthcare

PEEK has established itself as a critical material in the medical field, especially in the production of implants and prosthetics. Traditional manufacturing methods for medical devices often require costly molds and long lead times, but 3D printing with PEEK allows for the creation of custom-made parts with a shorter turnaround time and reduced cost. Additionally, PEEK’s biocompatibility and sterilization capabilities make it a safe option for use in the human body.

Examples of medical applications include spinal implants, hip replacements, and surgical guides, where precision, strength, and patient-specific customization are key.

3. Automotive Industry

In the automotive industry, weight reduction is a constant goal to improve fuel efficiency and overall performance. PEEK's lightweight yet strong characteristics make it a popular choice for 3D printing automotive components. It is used in the production of gears, bearings, seals, and other parts that require high strength and resistance to heat and chemicals.

4. Oil and Gas

The oil and gas industry operates in some of the harshest environments on earth, where materials need to withstand high temperatures, chemical exposure, and mechanical stress. PEEK’s resistance to extreme conditions makes it a go-to material for critical parts such as valves, seals, and connectors used in oil rigs and pipelines. The ability to 3D print these parts offers cost-effective solutions for customization and on-demand production.

5. Consumer Electronics

While PEEK is not commonly used in consumer electronics due to its cost, it does find its way into high-end products that require durability and heat resistance, such as connectors, housings, and other components in devices like smartphones, laptops, and industrial machines.

Challenges of PEEK 3D Printing

While PEEK is an outstanding material for many applications, it does present challenges when it comes to 3D printing. Due to its high melting point (around 343°C), PEEK requires specialized 3D printers that can reach and maintain such temperatures. This can increase the initial cost of equipment for companies looking to incorporate PEEK 3D printing into their processes.

Additionally, PEEK filaments can be more expensive compared to standard 3D printing materials like PLA or ABS. However, the superior performance characteristics of PEEK often justify the higher material cost, especially in demanding applications.

Conclusion

PEEK 3D printing is a game-changer for industries that require materials with exceptional mechanical properties, heat resistance, and durability. With applications spanning aerospace, medical, automotive, and oil and gas industries, PEEK is solidifying its position as a go-to material for high-performance 3D printing.

As 3D printing technology continues to advance and more businesses invest in specialized equipment for PEEK, the material's availability and accessibility will increase, making it a more affordable and viable option for an even broader range of applications. For companies looking to push the limits of innovation, PEEK 3D printing is certainly an exciting area to watch in the future of manufacturing.