QGM Block Making Machine: Revolutionizing the Concrete Block Industry

2024-12-05

The construction industry is constantly evolving, with an ever-growing need for efficient, cost-effective, and high-quality building materials. Among the various innovations that have transformed construction, the QGM Block Making Machine stands out as one of the most influential. These machines are designed to manufacture concrete blocks with precision and efficiency, ensuring that builders have access to durable and sustainable materials for a wide range of construction projects.

In this blog, we’ll dive into what QGM Block Making Machines are, their features, benefits, and how they are changing the face of modern construction.

What is a QGM Block Making Machine?

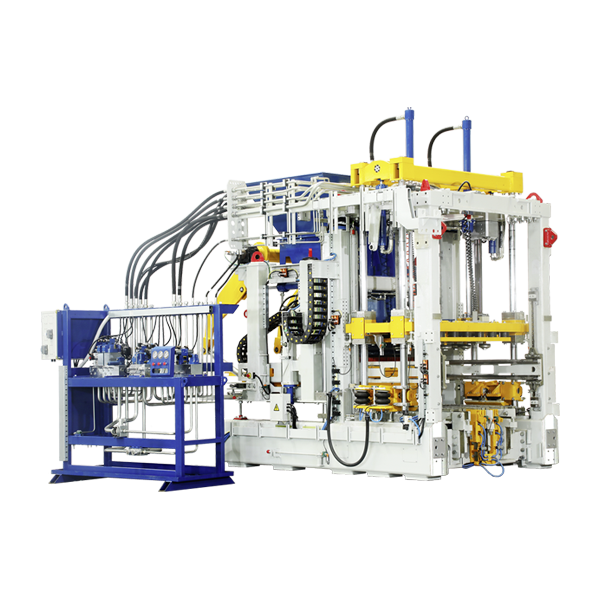

QGM (Quangong Machinery) is a leading manufacturer of concrete block making machines, providing solutions for the production of a wide variety of concrete products, including hollow blocks, paving stones, solid bricks, and other types of precast concrete materials. These machines are equipped with state-of-the-art technology and designed to meet the growing demand for high-quality, efficient block production.

The QGM Block Making Machine automates the entire process, from mixing raw materials to forming and curing the blocks. By utilizing advanced hydraulic systems, vibration technology, and user-friendly controls, these machines are able to produce blocks with high accuracy and uniformity.

Key Features of QGM Block Making Machines

1. Advanced Automation: QGM block making machines feature automatic production lines that require minimal manual labor. This helps increase productivity and reduces human error. Automation also leads to faster production cycles, enabling manufacturers to meet large-scale demands.

2. Versatility: One of the standout features of QGM Block Making Machines is their ability to produce a wide variety of concrete products. Whether you need hollow blocks for residential buildings, solid bricks for industrial projects, or decorative paving stones, QGM machines can cater to different requirements.

3. High Precision and Quality: QGM machines are designed to ensure that every block produced meets strict quality standards. The automated process guarantees uniformity in size, shape, and strength, which is essential for meeting construction specifications and ensuring the durability of the structures.

4. Energy Efficiency: These machines are engineered with energy-saving features, such as efficient hydraulic systems and optimized vibration mechanisms, to minimize energy consumption during production. This contributes to lower operational costs and a smaller carbon footprint.

5. User-Friendly Control Systems: QGM Block Making Machines come equipped with intuitive control panels, making it easy for operators to monitor and control the entire production process. These systems allow for real-time adjustments to ensure optimal performance.

6. Durability and Reliability: Built with high-quality materials and precision engineering, QGM machines are known for their long lifespan and reliability. They are designed to withstand the harsh conditions of industrial production environments and require minimal maintenance.

Benefits of Using QGM Block Making Machines

1. Increased Production Capacity: With their high automation and advanced technology, QGM Block Making Machines significantly increase production capacity. This enables manufacturers to meet growing demand, whether for small-scale residential projects or large-scale infrastructure developments.

2. Cost Efficiency: While the initial investment in a QGM Block Making Machine might be substantial, the long-term savings are considerable. The reduced need for manual labor, minimized waste, and lower energy consumption lead to substantial cost savings over time.

3. Customization Options: The versatility of QGM machines allows for customization in terms of the type of block being produced. This adaptability makes them an ideal choice for manufacturers who need to cater to specific project requirements or adjust to changing market demands.

4. Environmental Sustainability: In today’s world, environmental sustainability is a major consideration in every industry. QGM Block Making Machines contribute to sustainability by optimizing the use of raw materials and reducing waste during production. Additionally, the machines' energy efficiency helps to lower the carbon footprint of block manufacturing.

5. Enhanced Product Quality: The automated process of the QGM machine ensures consistent quality throughout each production cycle. Whether you're producing blocks for foundations, walls, or pavements, the strength, durability, and uniformity of the products are maintained to meet international standards.

6. Reduced Labor Costs: Automation reduces the need for a large workforce, cutting labor costs. Operators are only required to oversee the process, while the machine does the majority of the work. This leads to significant savings in labor expenses.

Applications of QGM Block Making Machines

QGM Block Making Machines are used in a wide range of construction projects, from residential homes to large commercial buildings and infrastructure projects. Some of the key applications include:

- Residential Construction: Hollow blocks, solid blocks, and other concrete products are used in the construction of houses, apartments, and other residential buildings.

- Commercial and Industrial Projects: Durable concrete blocks and paving stones are used for foundations, walls, and flooring in commercial and industrial buildings.

- Urban Infrastructure: Paving stones and curbs are produced for urban roadways, parking lots, and other infrastructure applications.

- Landscaping: Decorative blocks and stones are used for landscaping and garden design, creating aesthetically pleasing outdoor spaces.

Conclusion

QGM Block Making Machines have revolutionized the concrete block production industry by providing an efficient, cost-effective, and sustainable solution for manufacturing a wide variety of concrete products. Their advanced features, such as automation, versatility, energy efficiency, and consistent product quality, make them an essential tool for modern construction businesses.

As the demand for high-quality building materials continues to grow, the role of QGM Block Making Machines in supporting this need will only become more significant. Whether you're a small-scale manufacturer or a large construction company, investing in a QGM Block Making Machine is a step toward improving productivity, reducing costs, and delivering superior-quality concrete products for the construction industry.