Here's an overview of bimetallic barrels and their significance

2024-04-02

Bimetallic barrels are components used in the manufacturing of plastic processing machinery, particularly in injection molding and extrusion processes. These barrels are engineered using a bimetallic construction, which means they consist of two different metal alloys joined together. Here's an overview of bimetallic barrels and their significance:

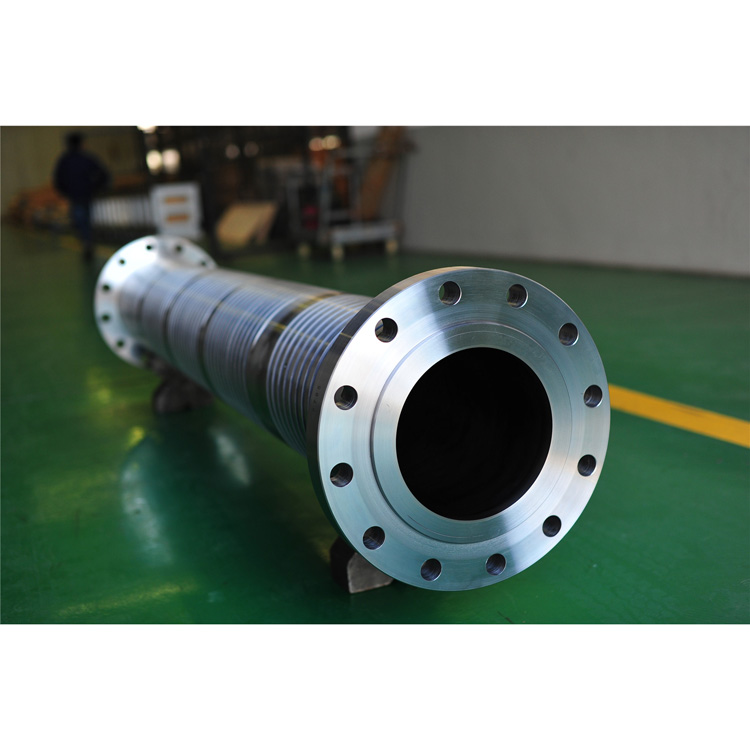

1. Construction: Bimetallic barrels are typically constructed with two layers: an inner layer and an outer layer. The inner layer, also known as the barrel liner, is made of a wear-resistant material such as iron-based alloys containing additives like chromium, tungsten, or nickel. This layer provides superior resistance to abrasion and corrosion caused by the high temperatures and abrasive nature of molten plastics. The outer layer, known as the barrel body or sleeve, is typically made of a tougher and more durable material such as carbon steel or alloy steel, providing structural strength and support.

2. Advantages:

- Enhanced Wear Resistance: The wear-resistant inner layer of bimetallic barrels significantly extends the service life of the barrel, reducing the frequency of replacements and downtime.

- Improved Corrosion Resistance: Bimetallic barrels are less susceptible to corrosion from acidic or corrosive plastics, chemicals, or processing conditions.

- Higher Processing Temperatures: The use of wear-resistant materials allows bimetallic barrels to withstand higher processing temperatures, enabling the processing of a wider range of plastics and engineering resins.

- Enhanced Performance: Bimetallic barrels provide consistent and reliable performance, resulting in improved product quality, higher productivity, and reduced maintenance costs.

3. Applications: Bimetallic barrels are used in various plastic processing applications, including injection molding machines, extrusion machines (e.g., single-screw and twin-screw extruders), blow molding machines, and other polymer processing equipment. They are employed in the production of a wide range of plastic products, such as packaging, automotive components, consumer goods, construction materials, and more.

4. Manufacturing Process: Bimetallic barrels are manufactured using advanced metallurgical processes such as centrifugal casting, metallurgical bonding, or powder metallurgy. These processes ensure a strong bond between the two layers, allowing for optimal heat transfer, mechanical strength, and wear resistance.

5. Maintenance and Repair: While bimetallic barrels offer excellent wear resistance, they may still require periodic maintenance or repair over time. Depending on the extent of wear or damage, the barrel liner can often be replaced or refurbished without replacing the entire barrel, saving time and cost.

Overall, bimetallic barrels play a critical role in plastic processing operations, offering superior wear and corrosion resistance, enhanced performance, and extended service life compared to conventional barrels. Their use contributes to increased productivity, reduced downtime, and improved product quality in the plastics industry.