Characteristics of Rigid-Flexible PCB

2023-11-06

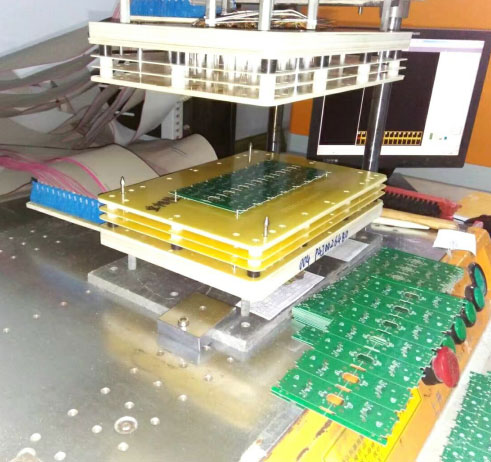

Rigid-Flexible PCB (Rigid-Flex PCB) is a type of printed circuit board that combines the features of both rigid and flexible PCBs in a single design. Rigid-Flex PCBs are used in applications where a combination of rigid and flexible circuitry is required to meet specific design and mechanical requirements. They offer advantages like space savings, reduced assembly, and improved reliability. Here are some key features and characteristics of Rigid-Flex PCBs:

1. Rigid and Flexible Sections: Rigid-Flex PCBs consist of both rigid sections, which are made of traditional rigid PCB materials (typically FR-4), and flexible sections, which are made of flexible materials like polyimide (PI) or polyester.

2. 3D Flexibility: Rigid-Flex PCBs can be bent and folded in three dimensions, allowing them to fit into complex and confined spaces. This is particularly useful in devices with tight packaging constraints.

3. Reduced Wiring: Rigid-Flex PCBs can replace traditional wire harnesses and connectors, reducing the need for additional components and simplifying assembly. This, in turn, enhances reliability and reduces the risk of loose connections.

4. Customization: Rigid-Flex PCBs can be highly customized to meet the specific requirements of a particular application. The combination of rigid and flexible sections can be tailored to the design needs.

5. Improved Reliability: The elimination of connectors and reduced wiring can improve the overall reliability of the PCB, as there are fewer points of failure.

6. Cost Efficiency: Rigid-Flex PCBs can reduce overall manufacturing costs by simplifying the assembly process and reducing the number of components.

7. Space Savings: They offer significant space savings, making them ideal for miniaturized electronic devices or those with complex geometries.

8. High-Density Circuits: Rigid-Flex PCBs can support high-density circuits with a mix of surface-mount and through-hole components, allowing for more functionality in a smaller space.

9. Environmental Resistance: They are designed to withstand various environmental factors, including heat, moisture, and vibration, depending on the materials used.

10. Connector Integration: Rigid-Flex PCBs can integrate connectors directly into the design, providing a reliable and secure connection between the rigid and flexible sections.

Rigid-Flex PCBs are commonly used in applications where the combination of flexible and rigid circuitry is necessary, such as aerospace, medical devices, automotive, and consumer electronics. They offer designers the flexibility to create more compact, reliable, and durable electronic devices while meeting the mechanical and environmental requirements of the application.