Ceramic Solid Wall Panel Equipment: Revolutionizing Modern Construction

2024-08-26

In the realm of modern construction, the demand for durable, aesthetically pleasing, and sustainable building materials is ever-increasing. Ceramic solid wall panels have emerged as a game-changer in this landscape, offering an innovative solution for creating high-quality, long-lasting walls. At the heart of this revolution is the specialized ceramic solid wall panel equipment that manufactures these advanced panels with precision and efficiency. In this blog, we will explore the significance of ceramic solid wall panels, the role of the equipment that produces them, and the benefits they bring to construction projects.

What Are Ceramic Solid Wall Panels?

Ceramic solid wall panels are wall cladding solutions made from ceramic materials, known for their strength, durability, and aesthetic appeal. Unlike traditional wall coverings, these panels are solid and provide a seamless, high-performance surface. They are used in a variety of applications, including residential, commercial, and industrial buildings.

Key Features of Ceramic Solid Wall Panels:

- Durability: Ceramic panels are highly resistant to wear, moisture, and chemical exposure, making them suitable for both interior and exterior applications.

- Aesthetic Appeal: Available in a wide range of colors, textures, and finishes, ceramic panels offer versatility in design and can mimic the look of natural stone, wood, or other materials.

- Low Maintenance: The non-porous surface of ceramic panels makes them easy to clean and maintain, reducing the need for frequent upkeep.

- Fire Resistance: Ceramic materials are naturally fire-resistant, enhancing the safety of buildings and contributing to fire prevention.

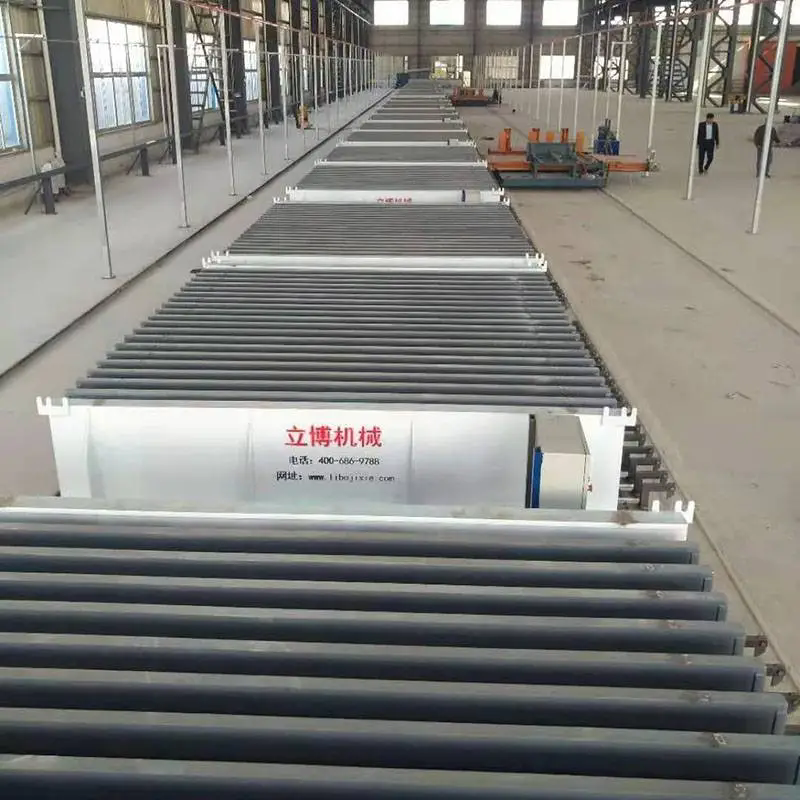

The Role of Ceramic Solid Wall Panel Equipment

The production of ceramic solid wall panels involves specialized equipment designed to handle the various stages of manufacturing, from mixing raw materials to forming and curing the panels. This equipment ensures that the panels meet high standards of quality and performance.

Key Types of Equipment in Ceramic Solid Wall Panel Production:

1. Raw Material Preparation Equipment:

- Mills and Crushers: These machines are used to grind and crush raw materials, such as clay and minerals, into fine powders. Proper preparation of raw materials is essential for achieving the desired properties of the ceramic panels.

- Blenders and Mixers: These devices ensure that the powdered materials are mixed thoroughly with water and additives to create a homogeneous slurry.

2. Forming Equipment:

- Extruders: Extruders are used to shape the ceramic slurry into the desired panel dimensions. They force the mixture through a mold, creating uniform panels with consistent thickness.

- Presses: Hydraulic or mechanical presses compress the ceramic material into panels, ensuring high density and strength.

3. Drying Equipment:

- Drying Chambers: After forming, the panels are dried to remove excess moisture. Drying chambers control temperature and humidity to prevent warping or cracking.

4. Firing Kilns:

- Kilns: The drying panels are then fired in kilns at high temperatures to vitrify the ceramic material. Firing is a critical process that enhances the panels' strength, durability, and resistance to environmental factors.

5. Finishing and Quality Control Equipment:

- Surface Treatment Machines: These machines apply finishes, glazes, or textures to the panels, adding to their aesthetic appeal and functional properties.

- Inspection and Testing Devices: Quality control equipment ensures that the panels meet industry standards and specifications. Tests may include checking for dimensional accuracy, strength, and surface defects.

Benefits of Ceramic Solid Wall Panel Equipment

1. Enhanced Precision: Advanced equipment ensures precise control over the manufacturing process, resulting in high-quality panels with consistent dimensions and properties.

2. Increased Efficiency: Automated systems and high-capacity machinery streamline production, reducing labor costs and increasing output.

3. Cost Savings: Efficient production processes and durable equipment contribute to lower overall production costs, making ceramic panels a cost-effective choice for builders and developers.

4. Customization: Modern equipment allows for customization of panel designs, textures, and finishes, providing flexibility to meet specific architectural and design requirements.

5. Sustainability: Many ceramic panel production systems incorporate eco-friendly practices, such as recycling waste materials and reducing energy consumption, aligning with sustainability goals.

6. Improved Safety: High-quality equipment ensures that the panels are produced to meet safety standards, including fire resistance and structural integrity.

Applications of Ceramic Solid Wall Panels

1. Residential Buildings: Ceramic panels are used for interior and exterior wall cladding, providing a stylish and durable finish for homes.

2. Commercial Spaces: Offices, retail stores, and hotels benefit from the aesthetic versatility and low maintenance of ceramic panels, enhancing their visual appeal and functionality.

3. Industrial Facilities: The durability and resistance of ceramic panels make them suitable for industrial environments, where they can withstand harsh conditions and heavy use.

4. Public Infrastructure: Ceramic panels are used in public buildings, such as schools and hospitals, for their durability and ease of cleaning.

5. Architectural Features: Designers and architects use ceramic panels to create striking visual effects and enhance building facades.

Conclusion

Ceramic solid wall panels represent a significant advancement in building materials, offering durability, aesthetic flexibility, and low maintenance. The specialized equipment used in their production plays a crucial role in ensuring that these panels meet high standards of quality and performance. From raw material preparation to finishing and quality control, each stage of the manufacturing process is optimized to produce panels that excel in both functionality and design. By investing in cutting-edge ceramic solid wall panel equipment, builders and manufacturers can deliver superior products that meet the demands of modern construction while contributing to sustainable practices and cost-effective solutions. Embrace the benefits of ceramic solid wall panels and experience the transformative impact they can have on your building projects.