Applications of Armoured Hoses

2024-06-12

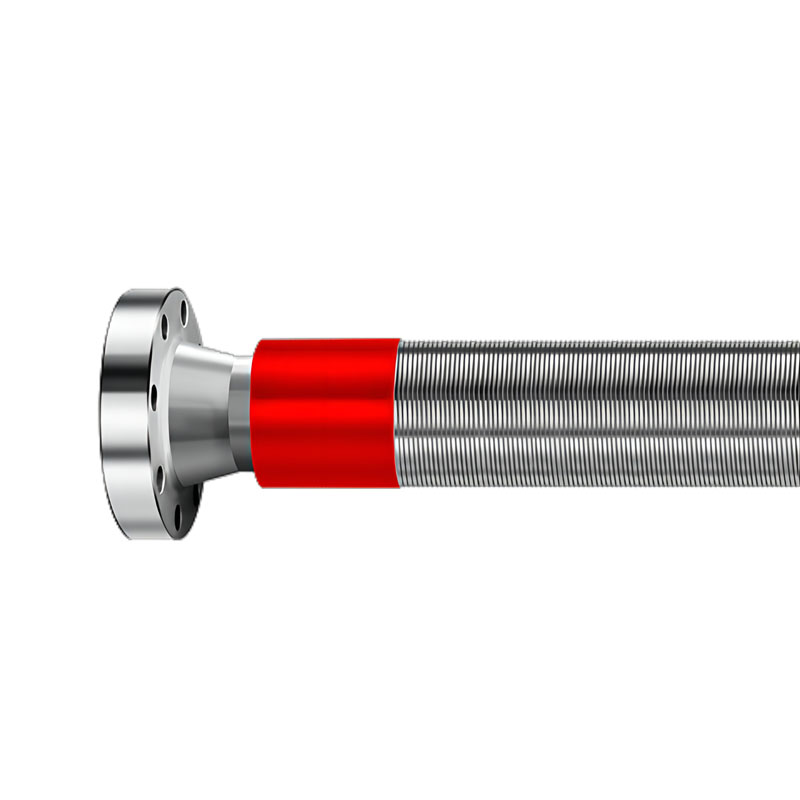

Armored hoses, also known as armored or armoured cables, are specialized hoses or cables that feature protective layers to withstand mechanical, environmental, or chemical stress. These hoses are commonly used in various industries such as oil and gas, mining, construction, and aerospace, where durability and reliability are crucial. Here's an overview of armored hoses, their features, applications, and benefits:

Features:

1. Protective Armor:

- Armored hoses are reinforced with protective armor layers, typically made of materials such as steel, stainless steel, or aluminum, to shield the hose from external damage and abrasion.

2. Flexible Core:

- Despite their protective armor, armored hoses maintain flexibility and maneuverability, allowing them to bend, twist, and move without compromising their structural integrity or performance.

3. Resilient Construction:

- Armored hoses are constructed with high-quality materials and manufacturing techniques to withstand harsh operating conditions, including extreme temperatures, pressure fluctuations, and exposure to chemicals or abrasive substances.

4. Corrosion Resistance:

- The protective armor of armored hoses provides resistance to corrosion, rust, and degradation caused by exposure to moisture, chemicals, saltwater, or other corrosive agents, ensuring long-term durability and reliability.

5. High Pressure Rating:

- Armored hoses are designed to handle high-pressure applications, making them suitable for conveying fluids, gases, or other substances under high-pressure conditions without leaking or bursting.

6. Temperature Resistance:

- Armored hoses are engineered to withstand a wide range of temperatures, from extreme cold to high heat, without degradation or loss of performance, making them suitable for use in diverse environments and applications.

7. Abrasion Resistance:

- The protective armor of armored hoses provides resistance to abrasion and wear, protecting the hose from damage caused by friction, impact, or contact with rough surfaces during operation or handling.

8. Customization Options:

- Armored hoses can be customized with different materials, sizes, lengths, and end fittings to meet specific application requirements and compatibility with existing systems or equipment.

Applications:

1. Oil and Gas Industry:

- Armored hoses are used for transferring oil, gas, and other petroleum products in drilling, production, refining, and transportation operations, where they provide reliable and leak-resistant fluid transfer solutions.

2. Mining and Quarrying:

- Armored hoses are employed in mining and quarrying operations for conveying water, slurry, chemicals, and abrasive materials in harsh and demanding environments, where they withstand rugged conditions and heavy-duty usage.

3. Construction and Infrastructure:

- Armored hoses are utilized in construction and infrastructure projects for pumping concrete, grout, and other construction materials, as well as for dewatering, irrigation, and drainage applications, where they ensure efficient and reliable fluid handling.

4. Aerospace and Defense:

- Armored hoses are used in aerospace and defense applications for conveying hydraulic fluids, fuel, lubricants, and other critical fluids in aircraft, spacecraft, military vehicles, and defense systems, where reliability and performance are paramount.

5. Marine and Offshore:

- Armored hoses are employed in marine and offshore industries for transferring fluids and gases on ships, offshore platforms, and subsea installations, where they withstand saltwater, corrosion, and extreme environmental conditions.

6. Industrial Manufacturing:

- Armored hoses find applications in various industrial manufacturing processes, such as chemical processing, food and beverage production, pharmaceutical manufacturing, and automotive assembly, where they provide reliable fluid transfer solutions for diverse applications.

Benefits:

1. Enhanced Durability:

- Armored hoses offer enhanced durability and longevity compared to standard hoses, thanks to their protective armor and robust construction, reducing maintenance requirements and downtime.

2. Increased Safety:

- The protective armor of armored hoses provides an additional layer of safety by minimizing the risk of leaks, bursts, or failures, ensuring safe and reliable operation in high-pressure and hazardous environments.

3. Versatility:

- Armored hoses are versatile and adaptable to a wide range of applications and industries, offering flexible solutions for fluid handling, conveying, and transfer requirements in diverse operating conditions.

4. Cost-Effectiveness:

- While initially more expensive than standard hoses, armored hoses offer long-term cost savings by reducing maintenance costs, downtime, and replacement frequency, resulting in improved overall efficiency and productivity.

5. Environmental Protection:

- Armored hoses help protect the environment by preventing leaks, spills, and contamination of soil, water, and air, ensuring compliance with environmental regulations and minimizing ecological impact.

Considerations:

1. Compatibility:

- Ensure that the armored hose is compatible with the fluid, gas, or substance being conveyed and compatible with existing systems, equipment, and operating conditions.

2. Installation and Maintenance:

- Follow proper installation procedures and maintenance practices to maximize the performance and lifespan of armored hoses, including regular inspection, cleaning, and replacement of worn or damaged components.

3. Regulatory Compliance:

- Consider regulatory requirements and industry standards when selecting armored hoses to ensure compliance with safety, quality, and environmental regulations applicable to your industry or application.

4. Specialized Requirements:

- For specialized applications or unique operating conditions, consult with manufacturers or suppliers to determine if custom-designed armored hoses are necessary to meet specific requirements and performance criteria.

Conclusion:

Armored hoses are essential components in various industries and applications where durability, reliability, and performance are critical requirements. By offering protection against mechanical, environmental, and chemical stress, armored hoses ensure safe and efficient fluid handling, conveying, and transfer operations in diverse operating conditions. When selecting armored hoses, consider factors such as material construction, protective features, application requirements, and regulatory compliance to choose the right hose for your specific needs and operating environment.