Discover Top Solar Panel Clamps Factories in China for Quality and Efficiency

2026-01-05

Welcome to our in-depth guide on the key players shaping the solar energy landscape. In a world increasingly turning to renewable sources, the quality and efficiency of solar panel installations hinge on reliable components—especially clamps. This blog will explore leading factories in China that specialize in these essential parts, offering insights into what makes them stand out. Among these innovators, Topfence has carved a niche with its commitment to durability and precision. Whether you're an installer, a manufacturer, or simply curious about sustainable solutions, join us as we uncover the top choices that can enhance your solar projects and drive forward the green energy revolution. Get ready to discover how these factories are powering a brighter, cleaner future.

Explore Leading Solar Panel Clamp Manufacturers in China

When it comes to solar panel installations, the clamps might seem like small components, but they play a huge role in ensuring panels stay securely mounted for years to come. China has become a key player in this niche, with manufacturers offering a wide array of clamping solutions designed to handle diverse environments and panel types. From residential rooftops to sprawling commercial farms, these companies are constantly innovating to improve durability and ease of installation.

Among the standout names, you'll find firms that specialize in aluminum and stainless steel clamps, which are favored for their corrosion resistance and lightweight properties. Some manufacturers have gained attention for their custom designs, allowing for precise fits with various mounting systems. This adaptability makes them a go-to choice for projects that require specific configurations or are located in areas with harsh weather conditions.

What really sets the top manufacturers apart is their commitment to quality control and sustainable practices. Many have implemented rigorous testing protocols to ensure their clamps can withstand high winds, heavy snow loads, and extreme temperatures. By focusing on these details, they help solar systems achieve longer lifespans and better performance, contributing to the overall growth of renewable energy adoption in markets around the world.

Key Features for High-Quality and Efficient Clamps

When it comes to selecting top-performing clamps, several crucial aspects set apart the best in the market. Durability is key—clamps should be crafted from robust materials like hardened steel or reinforced alloys to withstand heavy-duty use without bending or breaking. Additionally, a smooth, non-slip grip mechanism ensures precise control and safety, reducing slippage even under high pressure.

Efficiency often hinges on innovative design elements that enhance functionality. Look for clamps with quick-release levers or ergonomic handles that allow for swift adjustments and minimal effort during operation. Features like a wide throat depth or swivel pads can accommodate various workpiece sizes and shapes, making tasks more versatile and reducing the need for multiple tools.

Beyond basic operation, clamps that incorporate rust-resistant coatings or self-lubricating components offer long-term reliability, saving on maintenance costs. By focusing on these integrated traits, users can boost productivity while ensuring tools remain dependable over time.

How Chinese Factories Ensure Durability and Performance

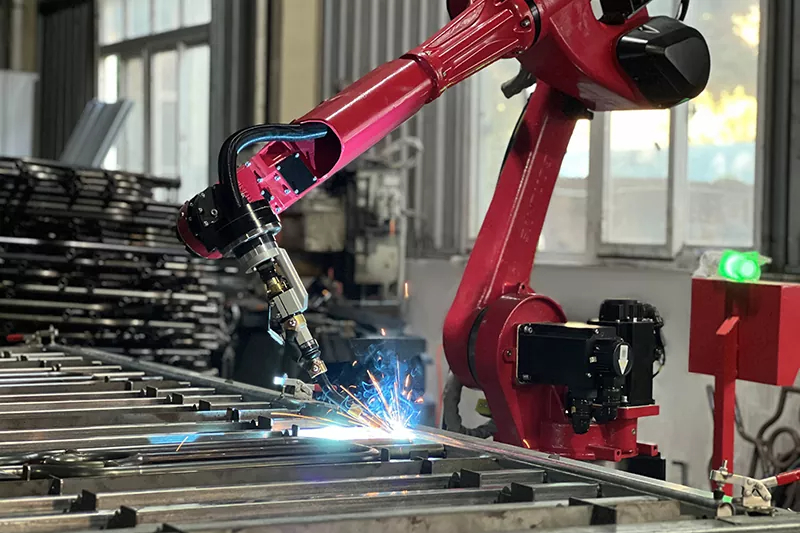

In the competitive landscape of global manufacturing, Chinese factories have carved out a niche by prioritizing durability and performance in their production lines. This focus goes beyond mere compliance with standards; it involves a deep-rooted commitment to iterative testing and quality audits at every stage. From sourcing robust raw materials like high-grade alloys and advanced polymers to implementing real-time monitoring systems, these facilities leverage both traditional craftsmanship and cutting-edge technology. For instance, many plants employ rigorous stress tests that simulate years of wear in controlled environments, ensuring that products not only meet but often exceed international benchmarks for longevity and reliability. This proactive approach minimizes defects and builds a reputation for resilience that resonates with buyers worldwide.

Another key aspect is the integration of specialized expertise and continuous innovation. Chinese manufacturers frequently collaborate with research institutions and engineering teams to refine designs and production techniques. This synergy leads to enhancements such as reinforced joints in machinery or improved thermal management in electronics, directly boosting performance metrics. Moreover, the adoption of automated precision tools and AI-driven quality control allows for consistent output without sacrificing the human touch needed for fine-tuning. Workers are trained to spot potential weaknesses early, fostering a culture where every team member contributes to durability goals, making the process both efficient and adaptable to evolving market demands.

Beyond technical measures, a holistic strategy ensures sustainability and long-term performance. Chinese factories invest in comprehensive maintenance protocols and supply chain robustness, reducing downtime and enhancing product lifecycle. By aligning with global standards and obtaining certifications like ISO, they demonstrate a transparent commitment to excellence that builds trust. This multifaceted effort—combining material science, skilled labor, and innovative processes—positions Chinese manufacturing as a leader in delivering durable, high-performing goods that stand the test of time, appealing to industries from automotive to consumer electronics.

Customization and Innovation in Solar Mounting Solutions

In the ever-evolving solar industry, customization isn't just an option—it's a necessity for maximizing energy yield and adapting to unique installation environments. Gone are the days of one-size-fits-all approaches; today's mounting solutions are tailored to specific rooftops, ground conditions, and even challenging terrains like hillsides or coastal areas. By offering bespoke designs, companies ensure panels are positioned optimally for sun exposure, reducing inefficiencies that can arise from standard systems. This personalized touch not only boosts performance but also simplifies installation, cutting down on labor costs and time. Whether it's adjusting for roof slopes or integrating with existing structures, customized mounts turn potential obstacles into seamless advantages, making solar power accessible in places once deemed unsuitable.

Innovation in solar mounting goes beyond simple adjustments, driving the industry forward with smart, adaptable technologies. Think of mounts that track the sun's path across the sky, automatically tilting panels to capture every ray of sunlight—this isn't futuristic; it's already enhancing efficiency in commercial and utility-scale projects. Meanwhile, lightweight, corrosion-resistant materials are redefining durability, especially in harsh climates where traditional systems might falter. These advancements aren't just about better performance; they also promote sustainability by using eco-friendly, recyclable components. As solar adoption grows, innovative mounts are paving the way for new applications, from floating solar farms on reservoirs to integrated systems on agricultural land, proving that creativity in design can unlock untapped potential.

What sets leading solutions apart is how they blend customization with innovation to deliver tangible benefits. Imagine a mounting system that's not only tailored for a specific rooftop but also incorporates modular designs, allowing easy expansion as energy needs grow. This flexibility empowers users to scale up without overhauling their entire setup, saving money and reducing waste. Additionally, by focusing on user-friendly installation features—like snap-together components or pre-assembled parts—innovators are making solar adoption more approachable for homeowners and businesses alike. It's this combination of personalization and cutting-edge tech that transforms solar projects from mere installations into long-term investments, ensuring they remain efficient and cost-effective for years to come.

Comparing Cost-Effectiveness Across Top Suppliers

Evaluating the cost-effectiveness of leading suppliers involves more than just comparing price tags at face value. It requires a deep dive into how each contender aligns with your specific operational needs and long-term goals. Factors like logistics efficiency, bulk order discounts, or customization options can dramatically shift the perceived value, making a supplier with a higher base price potentially more economical in practice. By considering these nuanced aspects, you can identify partners that not only save money upfront but also enhance overall project outcomes through reliability and tailored solutions.

Another key angle when assessing top suppliers is to look beyond direct costs to include hidden or indirect expenses that might not be immediately apparent. For instance, a supplier offering lower prices might incur additional charges for shipping delays, subpar quality leading to increased returns, or inadequate customer support that slows down operations. On the other hand, a slightly pricier option could provide superior after-sales service, robust warranty terms, or more flexible payment schedules, which collectively contribute to better cost management over time. This holistic approach ensures you're not just cutting corners but investing in a partnership that drives sustainable efficiency.

To stand out in this comparison, it’s essential to leverage real-world data and testimonials rather than relying solely on advertised rates. Engage with peer reviews, case studies, or trial periods to gauge how different suppliers perform under actual working conditions. This hands-on evaluation can reveal insights into aspects like innovation adoption, response times to market changes, or environmental sustainability practices, which may influence cost-effectiveness indirectly. By prioritizing suppliers that demonstrate tangible value through proven performance, you can make informed choices that boost competitive advantage and long-term savings, setting your procurement strategy apart from conventional, price-focused analyses.

Sustainable Practices in China's Solar Clamp Production

In recent years, China’s solar clamp production has taken significant strides toward environmental sustainability, driven by both regulatory pressures and growing global demand for eco-friendly components. Manufacturers are increasingly adopting circular economy principles, incorporating recycled metals like aluminum and steel into their designs. This not only reduces waste but also cuts carbon emissions during processing, making the entire supply chain more efficient. By sourcing materials locally whenever possible, companies minimize transportation-related pollution, further contributing to a greener product lifecycle.

Beyond material choices, technological innovations are playing a key role in enhancing sustainability. Many Chinese producers are investing in energy-efficient manufacturing processes, such as automated systems that optimize resource use and reduce water consumption. Some facilities have integrated solar panels to power operations directly, creating a self-sustaining loop that mirrors the renewable energy sector they serve. These advancements ensure that solar clamps are not just durable tools for mounting panels but also embody the clean energy values they support.

Looking forward, collaboration between industry leaders and policymakers is fostering a culture of continuous improvement in sustainability practices. Initiatives like green certification programs and transparent reporting on environmental impacts help build trust in the market. As China solidifies its position as a global leader in solar technology, these sustainable practices in clamp production set a benchmark, showing how practical manufacturing can align with broader ecological goals without compromising quality or affordability.

FAQ

Chinese factories often provide competitive pricing and large-scale production capabilities, making them ideal for bulk orders. Many have also invested in advanced technology to improve clamp durability and installation efficiency.

Look for manufacturers with certifications like ISO 9001, strong R&D departments, and positive client testimonials. Visiting factories or requesting samples can also help assess quality firsthand.

Yes, regions such as Guangdong, Jiangsu, and Zhejiang are hubs for manufacturing due to their developed industrial infrastructure and expertise in metalworking and solar products.

Top factories typically use aluminum alloys or stainless steel for their corrosion resistance and strength, ensuring long-term performance in various weather conditions.

They design clamps with user-friendly features like quick-fastening mechanisms and compatibility with standard panel sizes, reducing installation time and labor costs.

Many offer customization options for dimensions, coatings, and load capacities, allowing them to tailor products to unique solar array layouts or environmental requirements.

Check if they implement rigorous testing for factors like tensile strength and weather resistance, and inquire about their defect rates and post-sales support.

Prices vary based on material, order volume, and customization. Leading factories often provide transparent quotes and may offer discounts for long-term partnerships or large orders.

Conclusion

China stands as a pivotal hub for solar panel clamp manufacturing, hosting numerous leading factories that specialize in producing high-quality and efficient mounting solutions. These manufacturers excel in crafting clamps that prioritize durability and performance, often incorporating innovative designs and materials to withstand harsh environmental conditions. From aluminum alloys to stainless steel, the emphasis is on longevity and reliability, ensuring solar installations remain secure for decades. Additionally, many Chinese factories offer extensive customization options, allowing clients to tailor clamps to specific project needs, whether for residential, commercial, or utility-scale solar arrays. This flexibility, combined with a strong focus on research and development, drives continuous improvement in product efficiency and ease of installation.

Beyond product features, top suppliers in China are recognized for their cost-effectiveness, providing competitive pricing without compromising on quality. This economic advantage stems from economies of scale, advanced manufacturing processes, and efficient supply chains. Moreover, sustainable practices are increasingly integral to production, with many factories adopting eco-friendly measures such as using recycled materials and reducing energy consumption during manufacturing. By balancing innovation, customization, and affordability, these factories not only meet global demand but also contribute to the broader renewable energy transition. Overall, exploring China's solar panel clamp industry reveals a dynamic landscape where quality, efficiency, and sustainability converge to support the growth of solar power worldwide.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/